Choosing the right magnet for your project can be challenging, especially when deciding between ceramic magnets and neodymium magnets. These two materials are the most common options in today's market, but they offer very different performance, costs, and applications.

At AEMagnets, we've spent over a decade helping engineers, designers, and sourcing managers select the best magnet solution for their needs. In this guide, we'll break down the key differences between ceramic and neodymium magnets — including strength, durability, cost, and ideal use cases — so you can make an informed choice that fits your design and budget.

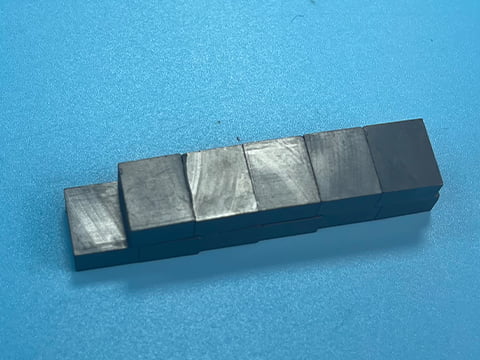

Ceramic magnets, also called ferrite magnets, are made from a mix of iron oxide and strontium carbonate. They are sintered into a hard, brittle material with good magnetic stability. Because the raw materials are inexpensive and widely available, ceramic magnets are one of the most cost-effective magnetic materials on the market.

Ceramic magnets are commonly used in products where moderate magnetic strength is enough, such as:

Neodymium magnets, also known as NdFeB magnets, are made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available today, offering a very high magnetic energy density. This means you can get powerful magnetic force even in a very small size, which makes them ideal for modern, compact designs.

Neodymium magnets are the preferred choice for applications where maximum strength in limited space is required, including:

When choosing between ceramic and neodymium magnets, it’s helpful to compare their most important properties side by side.

|

Factor |

Ceramic Magnets |

Neodymium Magnets |

|

Magnetic Strength |

Moderate strength — suitable for general use |

Very strong — up to 10× stronger than ceramic |

|

Size Requirement |

Larger magnets needed for same pull force |

Smaller magnets can achieve the same or higher force |

|

Temperature Resistance |

Good – work well up to ~250 °C |

Limited – standard grades work up to ~80–150 °C (special grades available for higher) |

|

Corrosion Resistance |

Naturally rust-resistant, no coating needed |

Require protective coating (NiCuNi, epoxy) to prevent rust |

|

Cost |

Low — very cost-effective for bulk applications |

Higher cost per kg and per piece |

|

Durability |

Hard and brittle, can chip if hit |

Harder but more prone to chipping without coating |

|

Availability |

Widely available in standard shapes and sizes |

Wide range of custom grades and precision options |

Selecting the right magnet depends on more than just magnetic strength — you also need to consider the application environment, available space, and budget. Here’s a simple way to decide:

When in doubt, it's best to consult with an experienced magnet manufacturer. At AEMagnets, we work closely with engineers and buyers to recommend the most suitable material and grade, helping you balance performance, durability, and cost.

While ceramic magnets naturally resist corrosion, neodymium magnets can easily rust if not protected. Coatings add a layer of durability and ensure long-term performance, especially in humid or outdoor environments.

When selecting neodymium magnets, match the coating to your application environment:

Working with a magnet manufacturer like AEMagnets ensures you get the right coating for your specific needs, reducing the risk of corrosion and product failure.

With over a decade of experience as a trusted Neodymium Magnets Manufacturer, AEMagnets supports engineers, product designers, and sourcing managers worldwide. We offer more than just magnets — we provide end-to-end solutions to help you choose the right material and design for your project.

Whether you need standard magnets or a fully customized solution, we can help you bring your project to market faster and with fewer design risks. Our goal is to make your design process easier, reduce trial-and-error costs, and deliver magnets that meet both technical requirements and budget expectations.

Both ceramic and neodymium magnets play important roles in modern applications — the best choice depends on your design goals, budget, and performance needs. Ceramic magnets deliver reliable, cost-effective performance for general uses, while neodymium magnets offer unmatched strength in compact spaces.

Choosing the right material is key to achieving the results you want. AEMagnets is ready to support you with expert advice, high-quality products, and flexible manufacturing options.

Posted on September 30, 2025 by MagnetAdmin

Posted on October 14, 2024 by MagnetAdmin

Posted on July 12, 2024 by MagnetAdmin

Posted on June 07, 2024 by MagnetAdmin

Posted on October 10, 2023 by MagnetAdmin

Posted on August 07, 2023 by MagnetAdmin

Posted on July 06, 2023 by MagnetAdmin

Posted on October 10, 2023 by MagnetAdmin

Posted on June 27, 2023 by MagnetAdmin

Posted on September 19, 2023 by MagnetAdmin